-

FDSP shares attending VIV Qingdao 2020 Asian International Intensive Livestock Exhibition

FDSP shares attending VIV Qingdao 2020 Asian International Intensive Livestock Exhibition -

FDSP attends global trade shows

FDSP attends global trade shows -

The aquatic feed production line successfully completed the export shipment and went to Uzbekistan

The aquatic feed production line successfully completed the export shipment and went to Uzbekistan -

“Jointly building the Belt and Road,continuously open development“---Striving to make South Korea 24TPH sludge with sawdust biomass pellet production line

“Jointly building the Belt and Road,continuously open development“---Striving to make South Korea 24TPH sludge with sawdust biomass pellet production line

Biomass Engineering equipment exported to South Korea

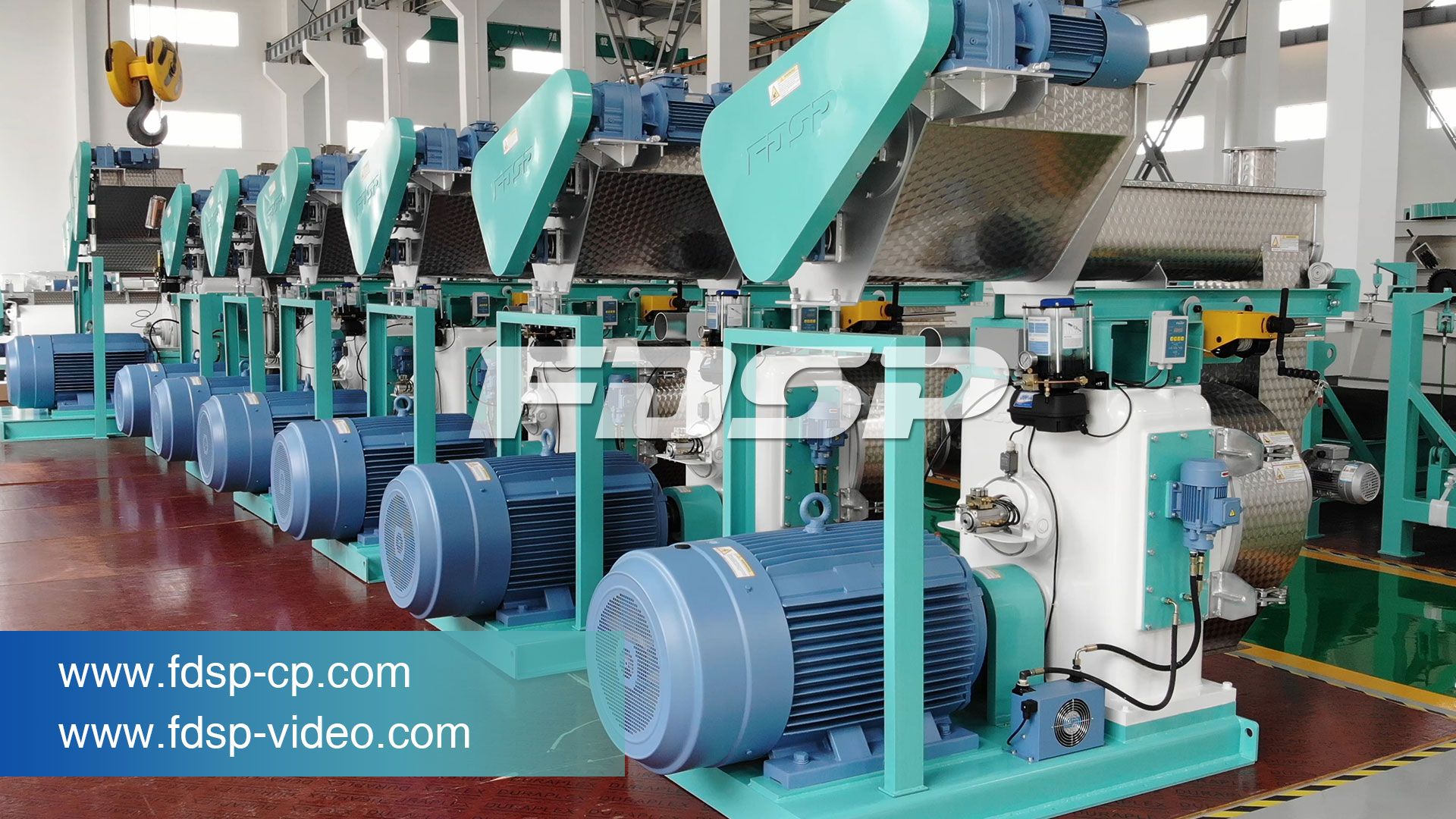

FDSP successfully completed the delivery of 12TPH sludge and sawdust pelleting production line for South Korea customers. This project is the third cooperation with FDSP after this customer bought 6 tph sludge and sawdust biomass pellet production line in the first phase and 6tph biomass production line in the second phase. Through these 3 times of continuous cooperation, fully show the customer’s affirmation on FDSP equipment operation performance, as well as recognition on FDSP comprehensive service. It demonstrates FDSP's craftsman spirit of "quality is seen in the real production, practice makes the real knowledge", as well as its sense of responsibility to deliver on time during the world epidemic.

The three phases of the 24TPH sludge-sawdust granulation production line adopt the FDSP mature sludge-sawdust biomass granulation production line process, equipped with 12 sets of the latest automatic 420 biomass pellet machine. The raw materials are mainly composed of dry sludge with sawdust, straw, and other crude fiber raw material mixture, among which the sludge is divided into industrial sludge and domestic sludge. After drying, grinding, storage, granulation, cooling, packaging (bulk), and other work section processing, turning waste into treasure and finally making into biomass clean energy. While promoting energy conservation and environmental protection, promote sustainable development of the world.