6-8tph chicken manure bio-organic pelleting line Fertilizer Engineering

Now take the 6-8 tph chicken manure organic fertilizer granulation production line as a case, according to the process and each section to do the following introduction and description.

Definition of production line of chicken manure bio-organic fertilizer

Chicken manure bio-organic fertilizer is a kind of biological organic manure that is use chicken manure as main raw materials and mixed with other organics, after fermentation, compost, pre-treatment, they finally make into biomass fertilizer. After the fermentation of chicken manure, it is a kind of high quality organic fertilizer. The nutrient content of chicken manure is very rich. It has a large amount of organic matter and a relatively high three-factor nutrient which contain organic matter content 25.5%, nitrogen 1.63%, phosphor 1.54%, potassium 0.85% and carbohydrate 11%, so chicken manure was an important organic fertilizer.

Flow process brief introduction

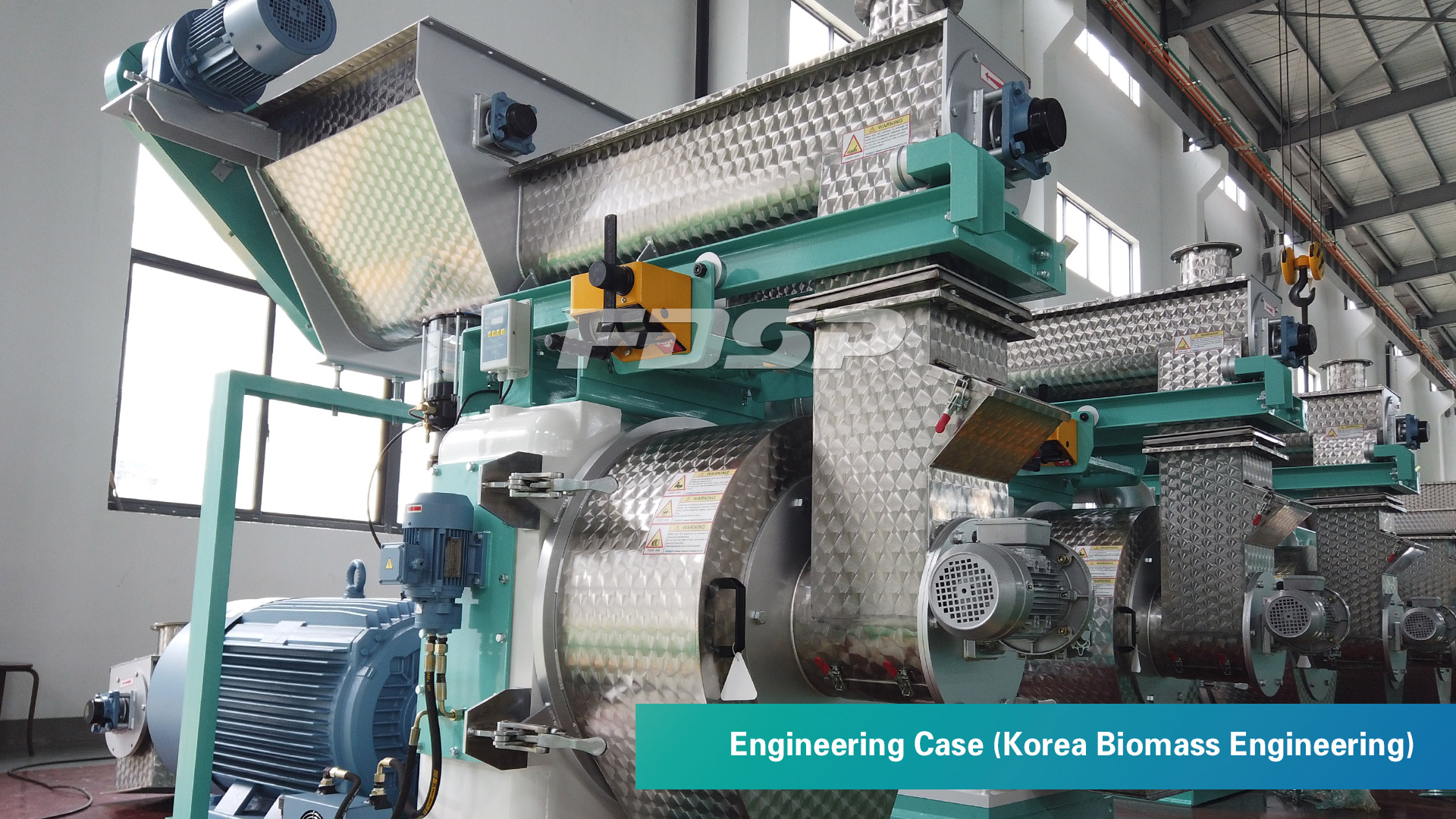

Two Line FZLH508 chicken manure biological organic fertilizer production line is by using of chicken manure to mix with some halm, straw, sawdust, or kitchen waste and other organic compounds on composting, fermentation, drying after pre-treatment, again into the processing workshop, through crushing, mixing, granulation, cooling, packaging section after processing, biological organic fertilizer, when the whole line to produce 6-8 tons of organic fertilizer granules, equipment total power is about 720 kw, the workshop covers an area of 3200 ㎡, contain raw material warehouse and finished product warehouse; The design of the whole line is compact, reasonable, meets the requirements of environmental protection, and can be directed according to customer requirements.