Professional Biomass Engineering 10tph wood pellet production line

The 10tph sawdust pellet production line, which was built by(FDSP) Jiangsu Liangyou Zhengda Co., Ltd., was fully completed in Indonesia and successfully accepted and put into operation. This project produces 10 tons/hour of wood scrap pelleting production line. The total power of the equipment is about 1848kw, the workshop covers an area of 3600㎡, including raw material warehouse and finished product warehouse. The whole line is compact in design, reasonable in structure, meets the requirements of environmental protection, and can be designed according to customer requirements.

Process flow: Indonesia biomass pellet production line output is 10T/H. There are a variety of raw materials, mainly forest small logs, wood door mill scraps, sawdust and shavings, etc. The raw materials are sliced -- crushed -- screened -- dried -- mixed -- pelletized -- cooled -- stored -- packed into finished biomass pellets.

Chipping section: The chipper processes the leftover material into wood chips with a size of 20-30mm and a thickness of 5-10mm, and then enters the subsequent section for processing. The chipper selected is our company's LYGX216 chipper, which can process wood with the maximum diameter of 120mm, host power of 55kw and output up to 10m3 /h.

Crushing section: The raw materials after the chipper are crushed in the hammer mill, and the grinding fineness is 3-4mm. There is no dust emission in this section. After crushing, the material will be delivered by the fan with negative pressure air suction. The hammer mill is a water droplet structure, the crushing rotor can be operated in reverse and forward direction, and the service life of the hammer can be improved. Direct motor drive mode is adopted. Crushing equipment: MFSP68×120, host power 200kw, output 6-8t /h.

Screening section: The sawdust raw material goes through the drum type precleaner to clear out some big impurities in the raw material, such as big wood blocks, hemp ropes, woven bags, stones, etc., so as to avoid such large impurities entering the equipment behind and causing equipment failure. Cleaning equipment (3 sets) : MCY160×300, power 3kw, hourly production: 5-8t/set

Drying section: The raw material moisture will be dried to about 15% through a three-layer roller dryer, and the wet sawdust will be directly dried in the dryer without being crushed. LYHG50 type three-layer roller dryer adopts three-return form, which is with high utilization of calorific value, small occupation area; The outer layer of the barrel is made of heat-resistant thermal insulation cotton. It is equipped with automatic furnace heating, high degree of automation. The dryer is equipped with infrared Mars detector, which can automatically start the spray system when Mars is detected in the discharge port. Drying equipment: LYHG50, drum diameter: 3.45m, length: 11.6m, power: 19kw, output: 5tph (raw material moisture: 40%)

Mixing section: The sawdust or shavings of different tree species are mixed by the mixing machine and then put into the granulating machine for granulating. Mixing equipment: SLHY5, host power 30KW, 10-15t per hour

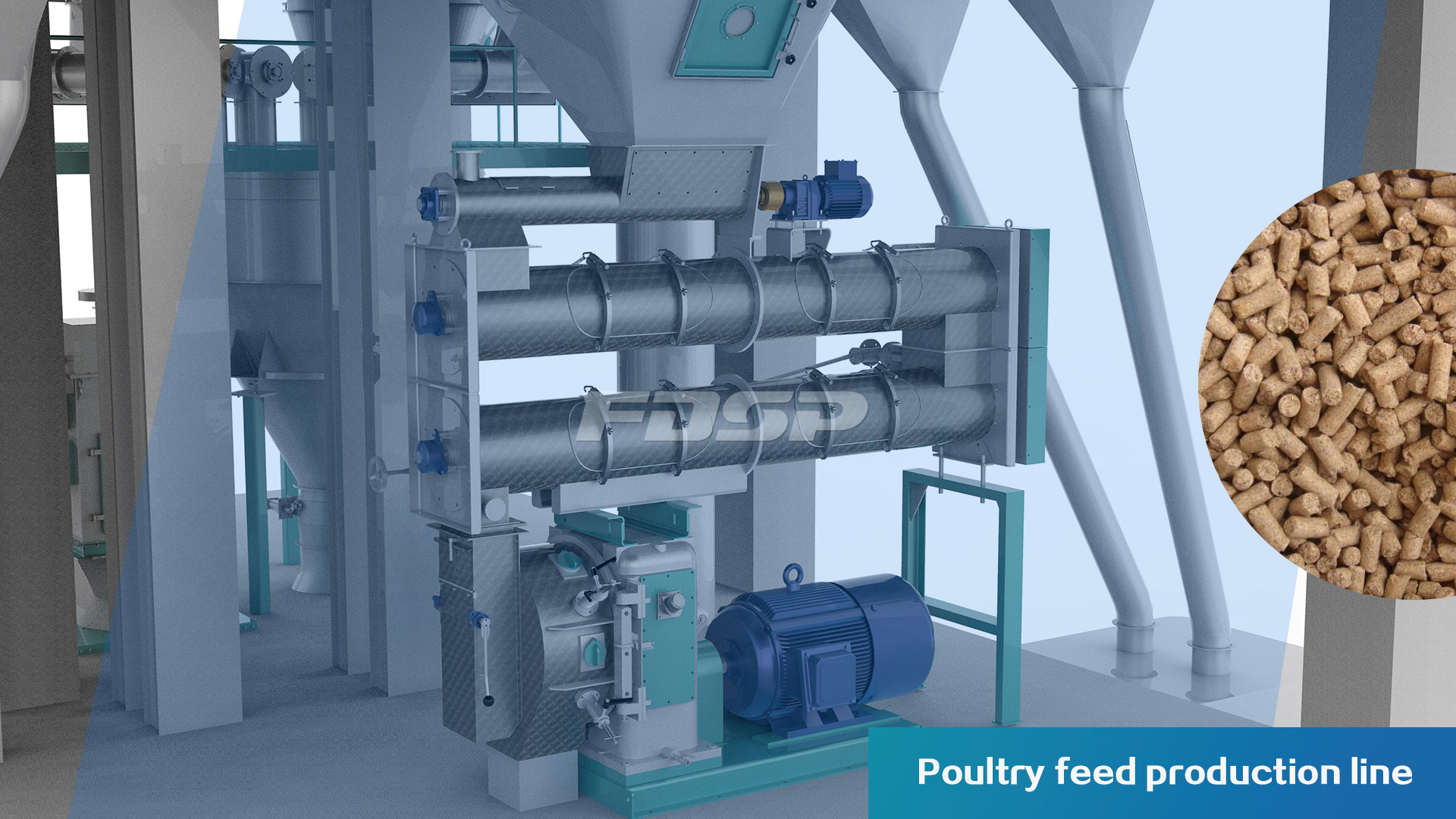

Pelleting section: Finally, the pelleting process is carried out. The finished particle diameter is optional from 6 to 10mm. The biomass pellet has the characteristics of high calorific value, no pollution and low ash content, which can be widely used in biomass power plants, biomass steam boilers, household fireplaces, drying stoves and biomass gasifiers, etc. Pelleting equipment (12 sets) : MZLH420, host power 90kw, forced feeder power 0.75kw, output 0.8-1.2t/set.

Cooling section: It is used to reduce the pellet temperature and water content. The pellet temperature after cooling is generally not higher than room temperature of 5℃, and the pellet water content after cooling is about 8-10%. Cooling equipment (2 sets) : MKLB4, cooling chamber volume 4m3, output 5-7t/set.

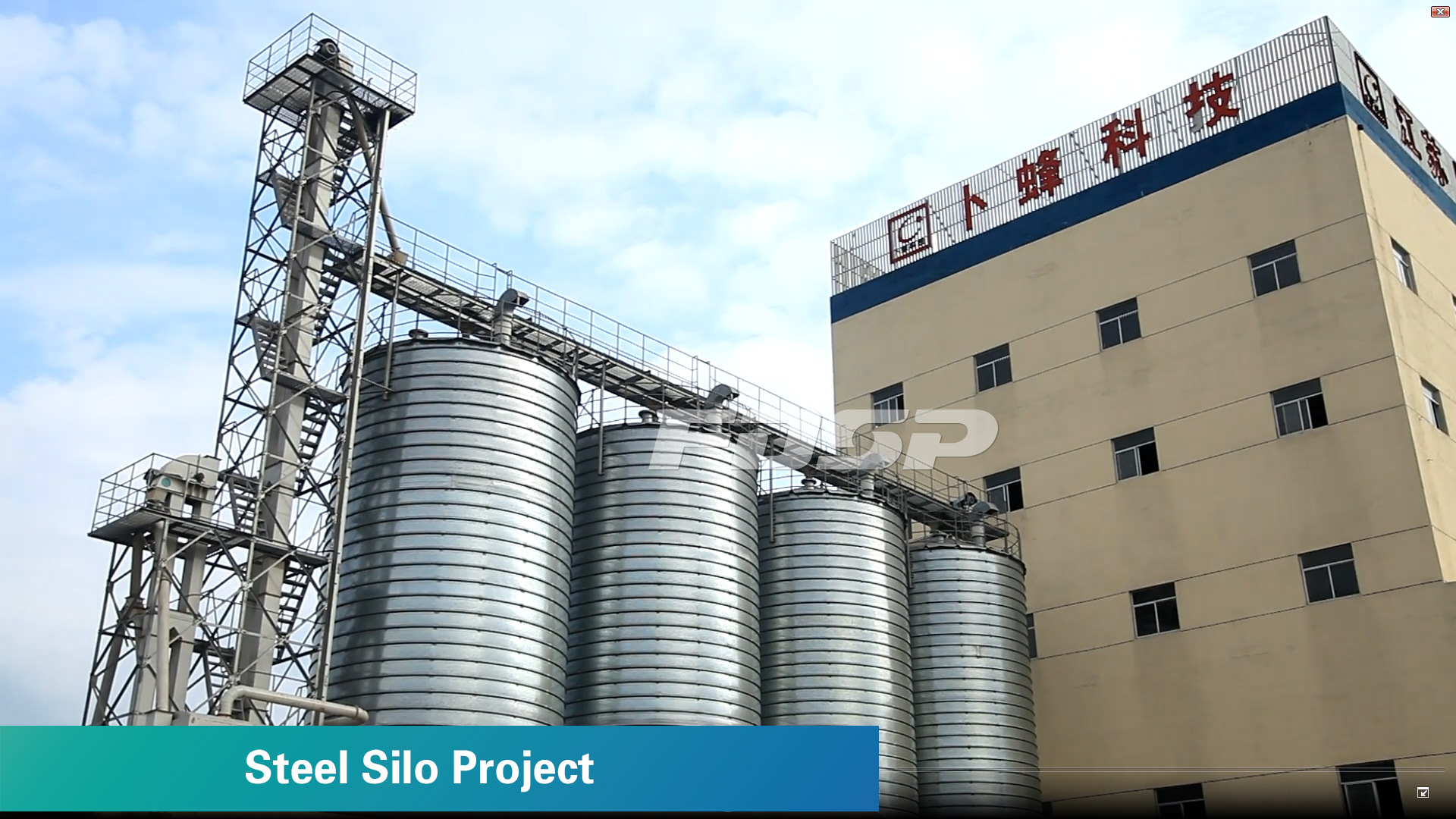

Storage section: In order to easy storage, the project is designed a storage bin of 5,000 tons of finished pellets. The finished pellets can be temporarily stored in the finished steel silo and transported out in bulk.

Packing section: When packing, you can choose the appropriate packing scale according to the customer's local sales needs so as to facilitate the customer to sell products. Generally, there are two specifications of small bags and ton bags. The package specifications of small bag packing scales are 20-50kg/ bag, and the package specifications of ton bag scales are 500-1000kg/ bag.

Jiangsu Liangyou Zhengda Co., Ltd. is specialized in the production of biomass pellet fuel complete shaping equipment, can provide customers with wood, wood chips, shavings and other raw materials for biomass pelleting complete production line; Biomass pelleting production line with building templates, woodworking scraps as raw materials; Biomass pelleting production line with corn stalk, wheat stalk and straw as raw materials;Biomass pelleting production line with fruit shell, fruit residue and palm as raw materials; Biomass pelleting production line with crop waste, sludge and coal dust as raw materials. We customize various complete equipment solutions for customers to meet their different needs. Welcome new and regular customers to come to consult and negotiate.