Professional Single SZLH420(10tph) poultry feed production line manufacturers

China Main products Professional Single SZLH420(10tph) poultry feed production line manufacturers

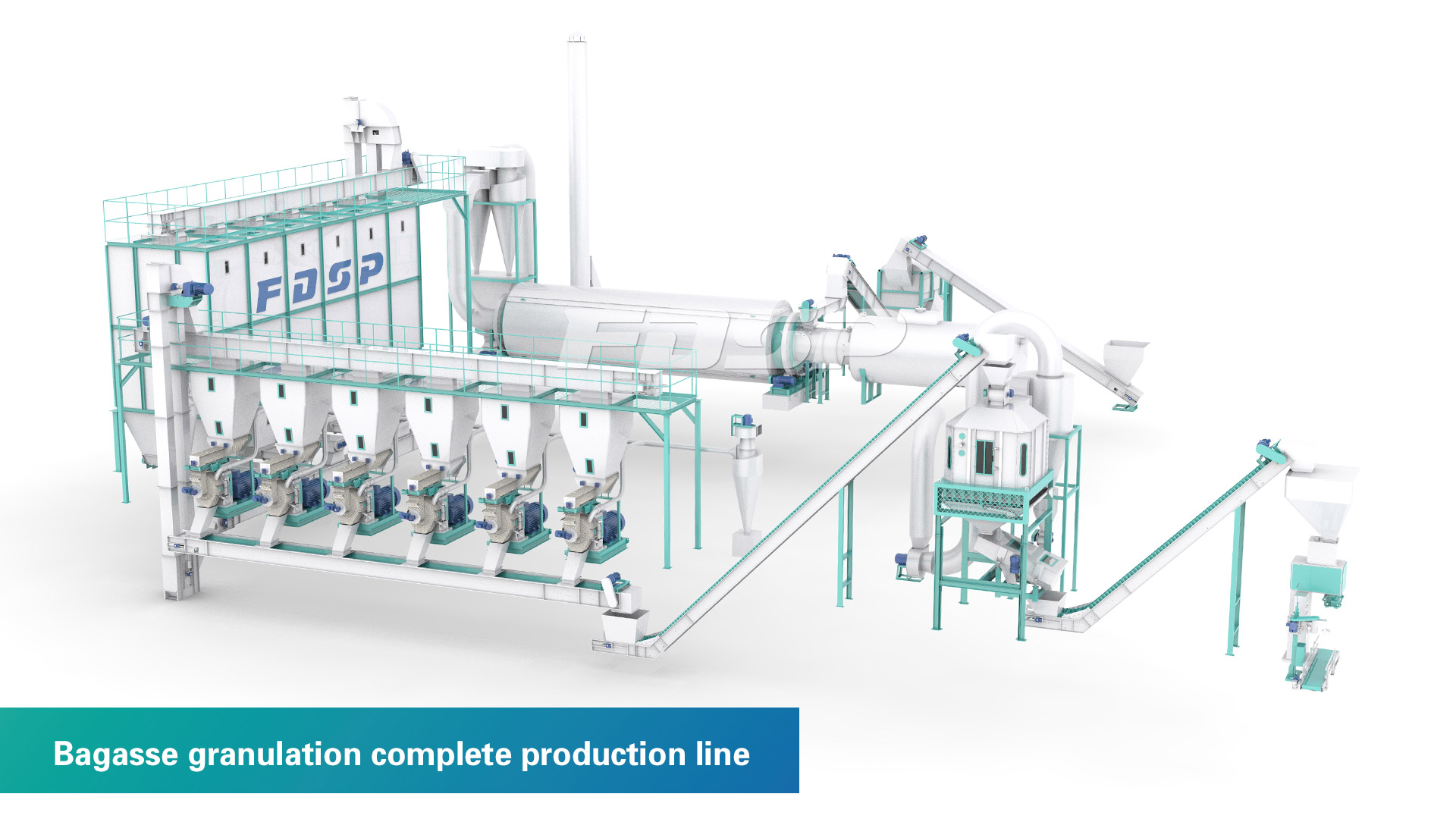

Jiangsu Liangyou Zhengda Co., Ltd is specialized in manufacturing feed machinery and engineering, we can offer customer complete machine solutions for livestock feed(pig and others) , poultry feed(chicken, duck, goose and others), ruminant feed(cattle, sheep and others), normal aqua feed(four major Chinese carps), special aqua feed(shrimp, crab and others), extruding aqua feed(floating and sinking fish feed, shrimp and others), premix feed(including various additives), pet food(cat food, dog food and others), we can meet customers' kinds of needs.

The features of poultry & livestock feed is that the crush fineness is moderate (the hole diameter of screen is 2-4mm), the curing degree is moderate (the pellet mill use double-layer conditioner), the diameter size of finish pellets is large (about 2.5-4mm). The capacity for SZLH420 livestock and poultry feed is designed to be 10tph, using one grinding process, double scale automatic dosing process, one mixing process, one pelleting process and one bagging process. The total power of this line is about 390kw, the working land size is about 16*11*26m, and matching 1ton boiler. The whole line has compact design, reasonable structure and meets the requirement of environmental protection. It can be customized according to customer’s requirements.

Technological characteristics and introductions:

RM receiving and cleaning process: In this process, the clean system for granule receiving and cleaning is separated from powder receiving and cleaning, dust collection are individual which is with the better effects.

Grinding process: 1set of hammer mill is adopt in this process, 3 grindings bins are equipped to cross crush different raw material; The impurities could be removed from raw material by magnetic separation equipment before grinding bins to ensure the safe running of hammer mill.

Batching and mixing process: in this process, we use 15pcs batching bins, two batching scale work at same time which is controlled by FDSP developed independently batching program, achieve accurate quick and slow feeding, quick batching and with high accuracy.

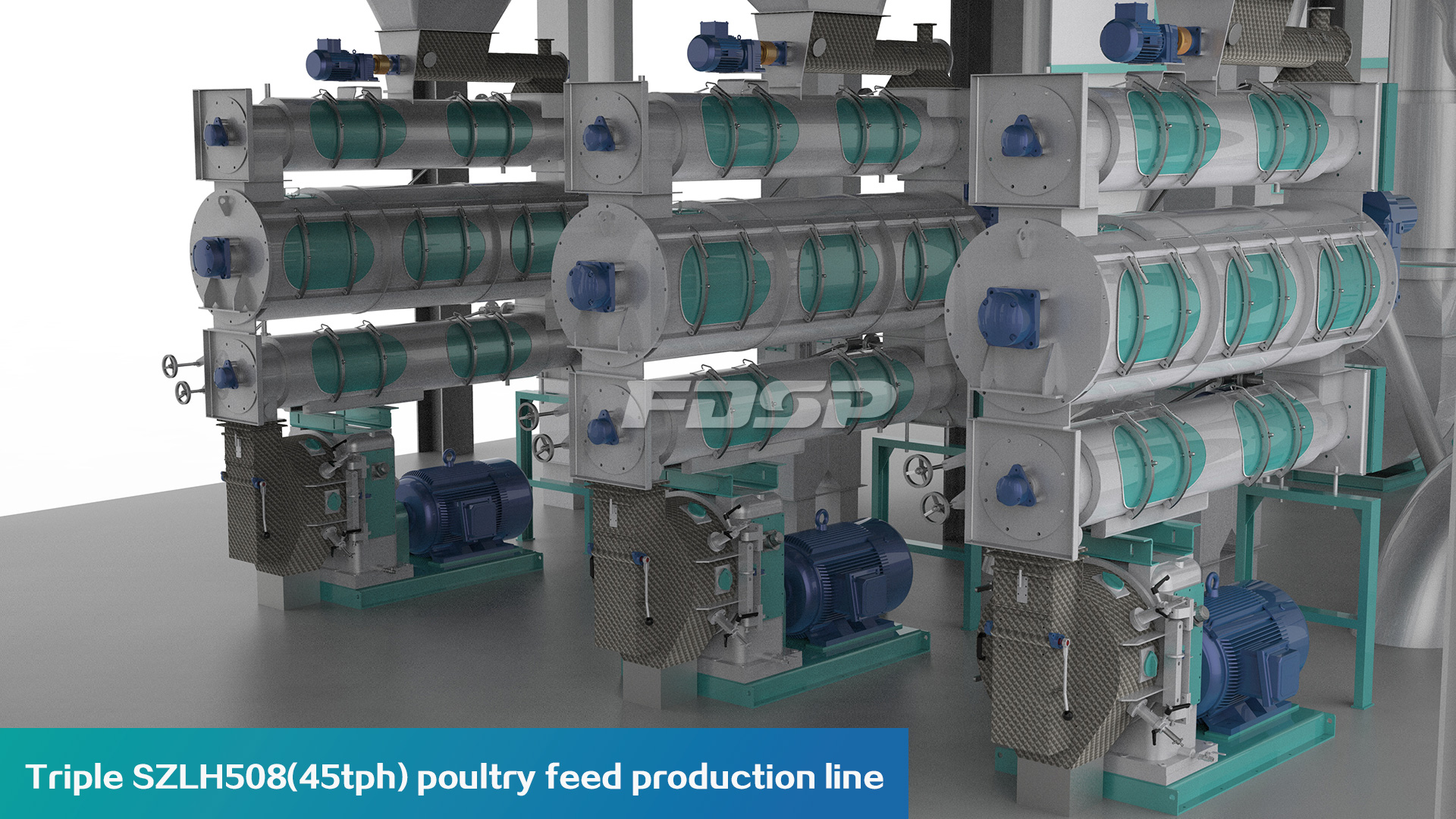

Granulation process: one set double conditioner pellet mill is used in this process. Two pellet bins are equipped for the pellet mill. After granulation, the pellets enter into the cooler, bucket elevator and then go to screening by rotary screener. The finished products go to the packing bins, others go back to the pellet mill other received by bags.

Packing process: There are 2 FP bins in this process, 1 of them only used for pellet finished products storage, the other can store both mesh feed and pellet feed. There is special anti-grading device for mesh feed bins. The pellet feed and mesh feed will be weighed and packed finally by packing scale.

The process can be optimized according to different customer needs:

1. Single point dust collection mode is used in the plan which means pulse filter is equipped for every rotary distributor(mesh) and granule cleaner with good effect. Single point dust collection is kind of humanized design of our company, to provide a better working environment, but the cost increases, customers can consider whether it is needed in actual situation;

2. The quantity of bins can be adjusted to achieve the beast use ratio and effectively control the production cost based on factors such as customers' formula, characteristics of raw materials.

3. oil post-coating system can be added in poultry finished feed pellets process to improve the pellet quality.